The radial clearance of high temp bearings includes the initial clearance, assembly clearance, and operating clearance. The operating clearance will directly affects the service life of the bearing and is influenced by factors such as installation conditions and operating conditions.

Clearance is an important technical parameter for the fit of rolling bearings, directly affecting technical performance such as load distribution, vibration, noise, wear, temperature rise, service life, and mechanical operation accuracy. The basic dynamic load rating of a bearing varies with the size of the clearance, and the recommended value of the basic dynamic load rating in bearing specifications is based on a working clearance of zero.

If the clearance is too large, the number of rolling elements carrying the load decreases, reducing the load-carrying capacity of the bearing. This leads to increased stress on the rolling contact surfaces, decreased operating accuracy of the bearing, increased vibration and noise, and shortened service life. If the clearance is too small, it can cause the bearing to overheat, increase in temperature, and even result in bearing seizure during operation. Therefore, it is essential to select the appropriate clearance for bearings based on the bearing type, operating conditions, and other factors.

The factors influencing the radial operating clearance of high-temperature bearings and how to select the radial operating clearance appropriately will be discussed below.

1. Factors affecting the radial working clearance of High temperature Bearings

(1) Elastic contact deformation of rolling elements and rings

Under the action of working load, the radial force of high-temperature bearings causes the inner ring to produce elastic contact deformation and expand, thereby causing the radial clearance of the bearing to decrease. The reduction amount is [1]6. 3 ×106×DwlΔ ′1 = 28 ×10- 6FrZllgFr(mm)(1) Where: Fr is the radial load, N; Dw is the roller diameter, mm; l is the roller length, mm; Z is the number of rollers. Similarly, under the action of radial force, the outer ring of the bearing will also produce elastic contact deformation and expand, thereby causing the radial clearance of the bearing to increase by [1]9. 1 ×106×DwlΔ 〃1 = 28 ×10- 6FrZllgFr(mm)(2) Comparing equations (1) and (2), it is known that under the action of Δ ′, the elastic contact deformation between the rolling element and the inner and outer rings results in an increase in the radial clearance of the bearing, and the increase is Δ1=Δ 〃11<Δ 〃1. Under the working load of 1- Δ ′

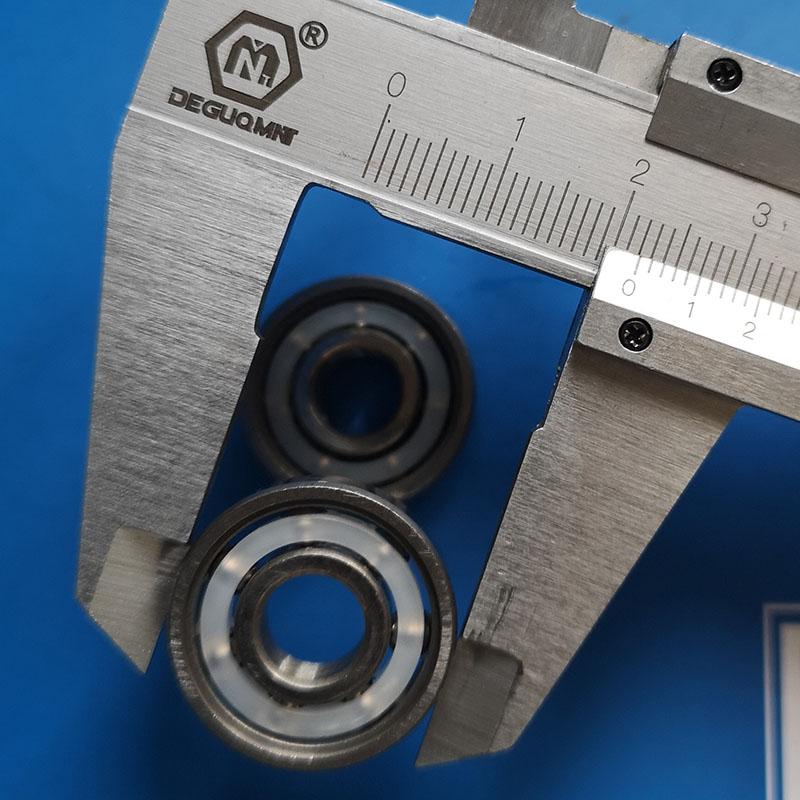

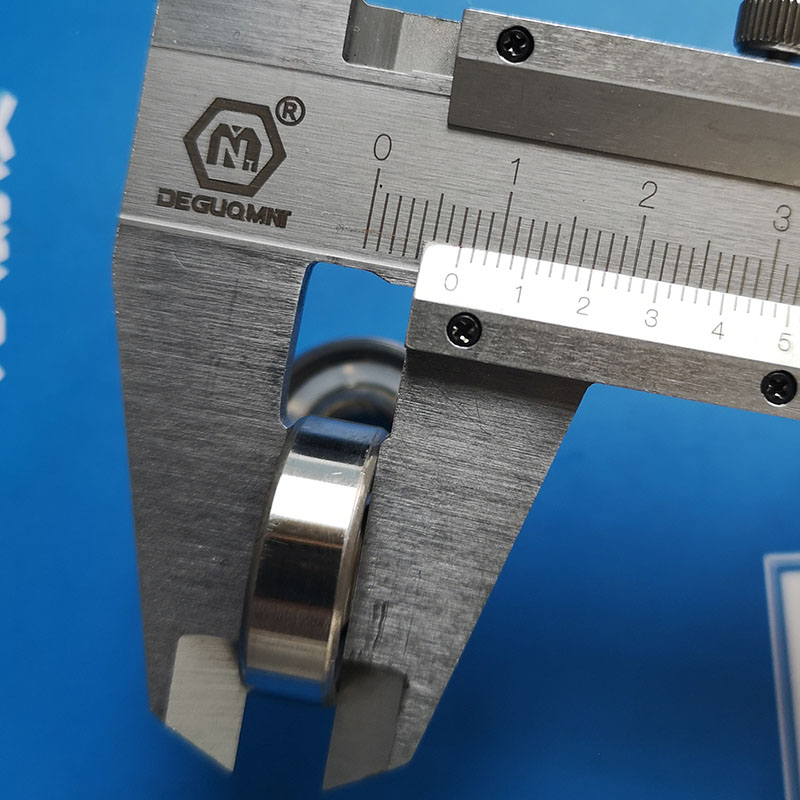

(2) Interference fit between the ring and the shaft neck and the bearing seat

The inner and outer rings of the bearing are respectively connected to the shaft neck and the bearing seat by interference fit. The interference will cause the original clearance of the bearing to change and form an assembly clearance. The interference fit between the inner ring and the shaft neck makes it expand slightly, while the interference fit between the outer ring and the bearing seat makes it shrink. The overall effect results in a reduction in the radial clearance of the bearing. For cylindrical roller bearings, the inner and outer rings can be regarded as thick-walled cylinders. According to the elastic thick ring theory [2-4], the deformation of the inner and outer rings due to interference fit can be obtained, that is, the reduction in bearing clearance.

(3) Elasticity between rolling elements and rings

When the rolling elements and the inner and outer ring raceways of the fluid dynamic lubrication oil film bearing are in operation, elastic deformation occurs, and an elastic fluid dynamic lubrication oil film is formed between the contact surfaces. The thickness of the oil film is related to the surface roughness of the bearing rollers and the two contact surfaces. In the state of complete elastic fluid lubrication, the load is entirely borne by the oil film. In fact, when the bearing is working, the rollers and the inner and outer ring raceways are mostly mixed lubrication, and the load is borne by the oil film and the matrix. The existence of the oil film thickness will reduce the radial clearance of the bearing.

The minimum oil film thickness between the roller and the inner and outer ring raceways is calculated using the Dowsow2Higginson formula [6]: hmin = 2.65α0.54(η0V)0.7ρ0.43E′(μm) where: α is the pressure viscosity coefficient of the lubricating oil, 1/MPa, and α = 2.2×10-2; η0 is the dynamic viscosity of the lubricating oil at atmospheric pressure, MPa s; V is the average linear velocity between the roller and the inner and outer ring raceways, mm/s; ρ is the equivalent radius, mm; the equivalent radius of the roller and the inner ring RiDw2 Ri+Dw (Ri is the inner ring raceway radius), the equivalent radius of the roller and the outer ring ρouter = ReDw2 Re-Dw (Re is the outer ring raceway radius); W is the load per unit length of the linear contact between the roller and the inner and outer ring raceways, N/mm; E′ is the comprehensive elastic modulus of the material, MPa, E′ = 1. 098 9 E, E is the elastic modulus. The minimum oil film thickness between the roller and the inner and outer ring raceways hminin and hminouter are calculated using formula (14), and the total oil film thickness between the roller and the inner and outer ring raceways is h = hminin + hminouter. The oil film thickness will reduce the radial clearance of the bearing, and the reduction is equal to the total oil film thickness between the roller and the inner and outer ring raceways, that is, Δ3 = hminin + hminouter (μm).

(4) Influence of bearing working temperature rise

During operation, the bearing will generate heat due to friction and other reasons, causing the temperature to rise. The magnitude of the friction temperature rise of the bearing can be expressed by the friction heat Q = 0.900 4Mn × 10- 4, where: M is the friction torque; n is the bearing speed, r/min. Under normal circumstances, the operating temperature of the bearing does not exceed 100 ℃. Since the surface area of the outer ring is larger than that of the inner ring, the heat dissipation speed is fast, making the temperature of the outer ring lower than that of the inner ring. Therefore, the thermal expansion of the inner ring is greater than that of the outer ring, resulting in a smaller clearance when the bearing is working than when installed. In addition, when the temperature rises, the temperature of the rolling element will also increase, causing (16) the clearance to be further reduced. The clearance reduction caused by the temperature difference between the inner and outer rings is [5]Δ4= Deα0Δt (mm) where: α0 is the linear expansion coefficient of the bearing steel, 1/℃, for steel α0= 1.12 × 10-5; Δt is the temperature difference between the inner and outer rings, usually taken as (17)510℃.

2. selection reasonable radial clearance for Ball bearings for high temperature applications

The above analysis shows the main factors affecting the radial clearance of rolling bearings. Among them, the elastic contact deformation between the rolling element and the inner and outer rings caused by the working load increases the radial clearance of the bearing, and the other factors reduce the radial clearance of the bearing. Considering the influence of other factors such as lubricating oil, rotation speed, bearing quality and assembly structure on the radial working clearance of the bearing, in order for the bearing to work normally, its radial working clearance Δ should satisfy the following formula Δ≥(Δ2+Δ3+Δ4- Δ1). After calculating the required radial working clearance of the bearing according to formula (18), select the appropriate (18) bearing according to the clearance group specified in the bearing standard.

MKL BEARINGS can produce High temperature bearings for Furnaces and kilns,Jet engines and gas turbines,Chemical processing,High-speed machining,Bakeries such as for car paint baking ovens, commercial pizza ovens, and carpet drying ovens. Glass plants,Conveyor systems,for more information just feel free to contact us at seven@mklbearing.com