As we move into 2025, the custom manufacturing landscape is evolving rapidly. The rise of advanced technologies, demand for greater efficiency, and an increasing focus on sustainability are reshaping the way products are designed, produced, and delivered. Companies that can adapt to these changes and embrace innovation will remain at the forefront of the industry. Here's a look at some of the top trends in custom manufacturing and how they’re influencing businesses worldwide.

1. Advanced Manufacturing Technologies Take Center Stage

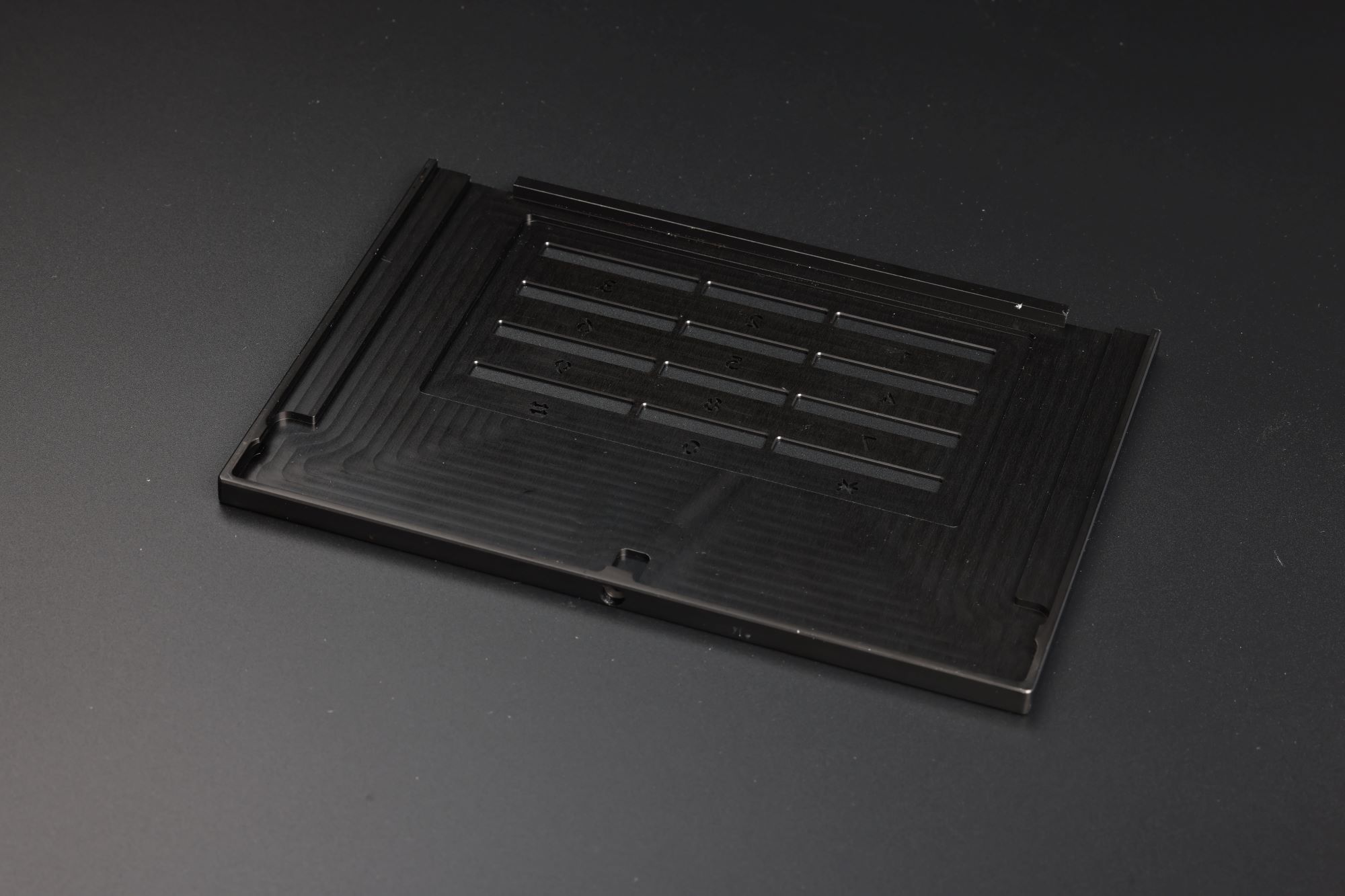

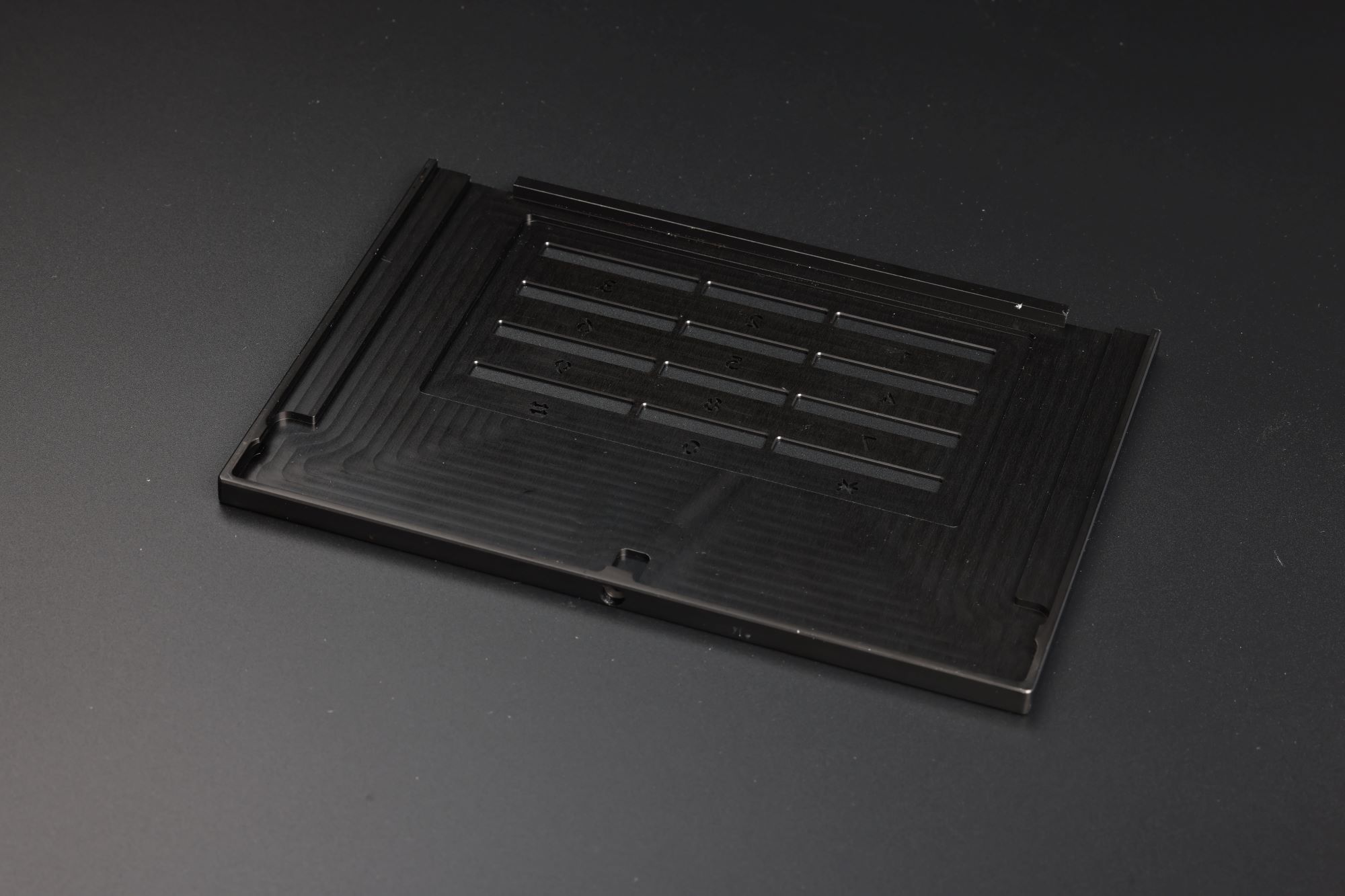

In 2025, cutting-edge technologies such as 3D printing, CNC machining, and automation are not just buzzwords—they are transforming the manufacturing process. These advancements allow for faster prototyping, improved precision, and more complex designs than ever before. For companies like ours, with state-of-the-art equipment and deep expertise in CNC machining, sheet metal fabrication, and injection molding, this trend means we can deliver high-quality custom parts with unmatched speed and precision. Whether you need rapid prototyping, small-batch production, or high-volume manufacturing, we are equipped to meet your needs with the highest level of efficiency.

2. Demand for Sustainability Drives New Practices

Sustainability is becoming a key focus in custom manufacturing, as businesses and consumers increasingly prioritize environmentally-friendly practices. Manufacturers are incorporating eco-friendly materials, reducing waste, and improving energy efficiency in their processes. Our company is committed to sustainability, not just through the materials we use but also through our lean manufacturing processes that minimize scrap and optimize resource use. By keeping up with these green initiatives, we are not only helping clients meet their sustainability goals but also contributing to a cleaner, more responsible future for the industry.

3. Customization at Scale—The New Competitive Edge

As consumer demand grows for tailored products, custom manufacturers are responding by providing more personalized solutions at scale. The ability to offer bespoke products without sacrificing production efficiency is increasingly becoming a differentiator in the market. Our company’s strength lies in our ability to provide end-to-end customization—from initial design and prototyping to full-scale production. With our comprehensive service offering, including CNC machining, injection molding, and surface treatment, we can meet the most intricate customer requirements, ensuring the final product perfectly matches their vision.

4. Shortened Lead Times and Speed to Market

In today’s fast-paced market, speed is everything. As companies aim to reduce time-to-market, the need for rapid prototyping and quick production has never been more critical. At our company, we specialize in meeting tight deadlines without compromising quality. Thanks to our advanced production equipment and ISO-certified quality management systems, we can offer quick turnarounds, from prototype to finished product. Our customers know they can rely on us for timely deliveries and flawless results, helping them maintain a competitive edge in their respective industries.

5. Globalization and the Need for Flexibility in Sourcing and Production

With global supply chains still in flux, businesses need manufacturing partners that can adapt quickly to changes in sourcing, materials, and logistics. Our global perspective, paired with a highly flexible production capacity, ensures we can handle orders from across the world while maintaining high standards of quality and service. Whether it's medical devices, consumer electronics, or automotive components, we’re prepared to meet the most stringent industry requirements and deliver customized solutions that help our clients stay ahead of the competition.

The Future of Custom Manufacturing is Here

As custom manufacturing continues to evolve in 2025, businesses need partners that combine cutting-edge technology, speed, and a commitment to quality. Our company stands at the forefront of these trends, with the capability to deliver superior products and services that meet the demands of today's market. Whether you’re looking to streamline your production process, reduce lead times, or create the next innovative product, we have the expertise, equipment, and commitment to help you succeed. Contact us today to discuss your custom manufacturing needs, and let’s take your project to the next level.