Advantage & Disadvantage of Carbon Steel Tube Sheets

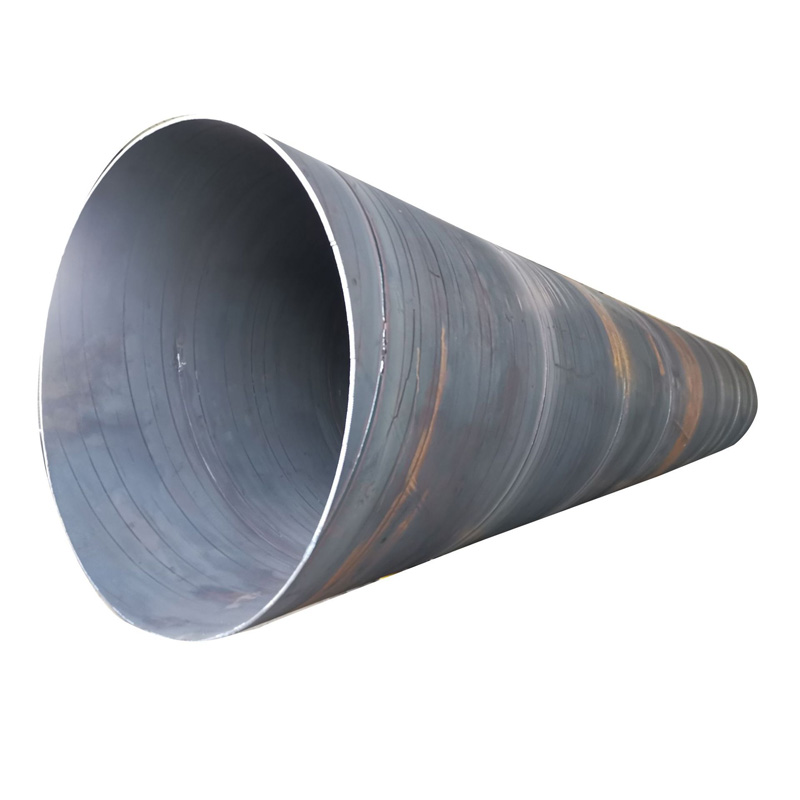

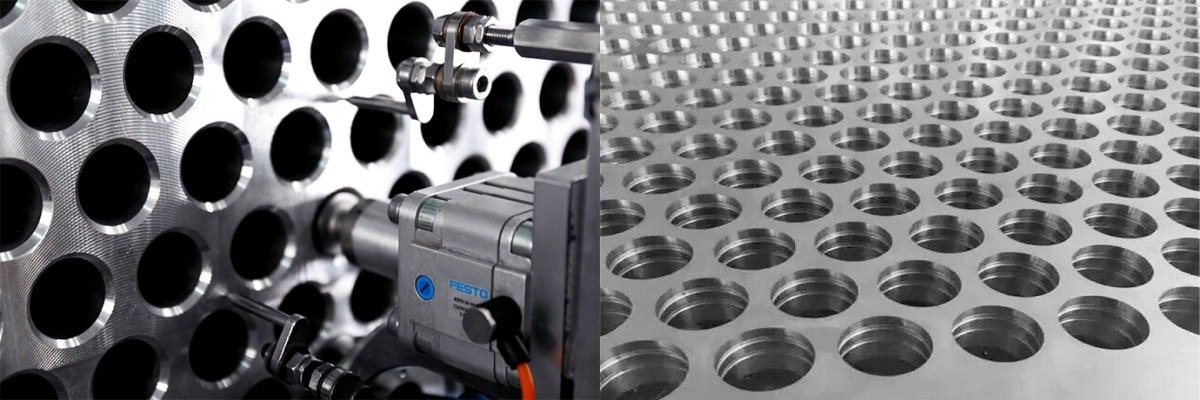

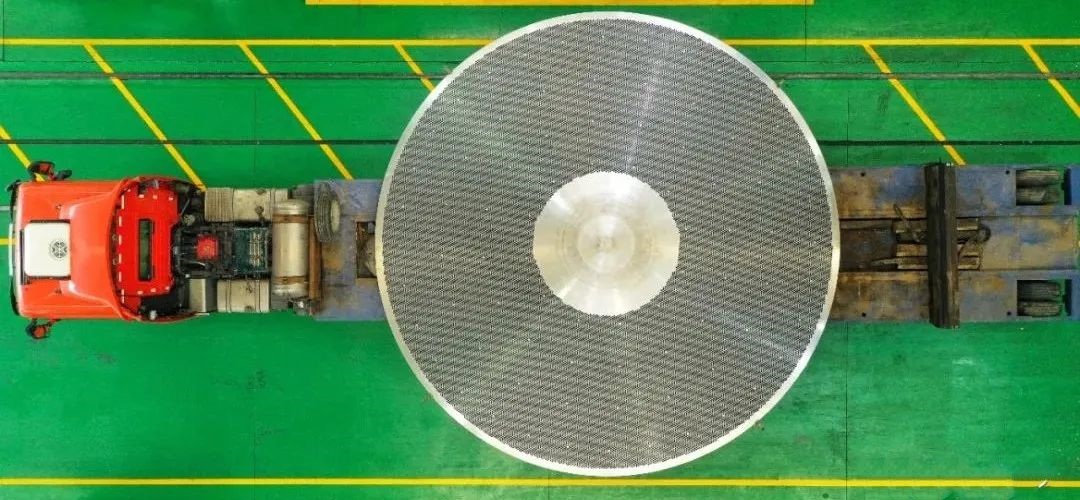

Tube sheet refers to the plate used for supporting and protecting pipelines. Pipelines are usually connected to the tubesheet through mechanical fixation or welding after drilling. In addition to serving as a fixing function, the pipe plate can also withstand the fluid and pressure inside the pipeline, reducing vibration and damage during operation. Carbon steel tube sheet, as a common tube sheet material, has a wide range of applications.

Carbon steel tube sheets are mainly composed of iron and carbon, which contain a high proportion of carbon elements, usually between 0.2% and 2.1%. In addition, it may also contain small amounts of elements such as manganese, silicon, and phosphorus, which can improve the strength and corrosion resistance of carbon steel plates. Here are some main advantages and disadvantages of carbon steel pipe sheets:

Advantages:

1. High cost-effectiveness: Carbon steel, as a common and economical material, is more affordable compared to other high alloy materials, making carbon steel pipe sheets the preferred choice in many applications.

2. High strength: Carbon steel is a type of steel with high strength, and its tensile strength is usually between 400-550MPa. This enables carbon steel plates to have high strength and rigidity under heavy loads and high pressures, enabling carbon steel pipe plates to maintain stability and reliability in high temperature and high pressure environments.

3. Good wear resistance: Carbon steel plates can achieve higher hardness and good wear resistance after heat treatment. Therefore, in some situations where wear resistance is required, carbon steel plate is the preferred material.

4. Easy to process and weld: Due to its low carbon content, carbon steel plates have good plasticity and weldability, and can be processed through various methods such as cold processing and hot processing. This makes the manufacturing and installation process of carbon steel pipe sheets relatively simple and efficient, reducing production costs and time.

5. Good environmental performance: Compared to other materials, carbon steel plates have better environmental performance. It can be recycled and reused to reduce resource waste and also reduce environmental pollution.

Disadvantages:

1. Easy to corrode: Carbon steel plates are prone to rusting, which is one of their biggest drawbacks. Due to the high content of iron in carbon steel plates, rust will occur when they react with oxygen in the air. This not only affects the appearance, but also leads to corrosion and damage to the surface of the board. Compared to stainless steel and other high alloy materials, carbon steel is more prone to corrosion in corrosive environments such as humidity, acidity, and alkalinity, which may lead to damage and shortened lifespan of the tube plate. To address corrosion issues, surface coatings or the use of anti-corrosion coatings can be used to enhance the corrosion resistance of carbon steel pipe sheets.

2. Not suitable for high temperature and strong acid environments: Carbon steel has lower temperature and acid resistance than high alloy materials, so in some applications that require high temperature or acidic media, carbon steel pipe sheets may not be suitable. This drawback can be avoided by welding other alloy materials to alter the performance of the contact surface.

3. Heavy weight: Compared to some lightweight alloy materials, carbon steel pipe sheets are relatively heavy, which may increase installation and maintenance difficulties.

In summary, carbon steel pipe sheets have advantages such as high cost-effectiveness, high strength, and ease of processing. However, their corrosion resistance, temperature resistance, and weight need to be evaluated based on specific application environments, and suitable materials should be selected to meet the requirements.