Circulation pumps are essential components in various home applications, such as heat pump systems, HVAC, domestic water supply, industrial water supply, and wall hung gas boiler systems. Shinhoo offers six categories of circulation pumps designed to cater to these specific home applications.

High Efficiency Circulator Pumps

High Efficiency circulator pumps are versatile and suitable for multiple applications, including HVAC, heat pump systems, domestic water supply, and industrial water supply. These pumps are designed to deliver excellent energy efficiency, resulting in reduced energy consumption and lower utility costs. Their advanced features, such as variable speed control and intelligent controls, optimize performance and enhance system reliability. To choose the right model, consider factors such as flow rate, head, DN, and motor efficiency to ensure compatibility with your specific requirements. Shinhoo's product line includes Classic, Master, and Mega series, offering varying specifications to meet different application needs.

Heat Pump Circulator Pumps

For efficient heat distribution in HVAC and heat pump systems, Shinhoo's Heat Pump Circulator Pumps are the ideal choice. These pumps are specifically designed to optimize heat transfer and ensure smooth circulation of water. Depending on your heat pump system's size and requirements, select the appropriate model from Shinhoo's range, which includes Master H, and Grand series. Consider factors such as flow rate, head, pressure, and compatibility with your heat pump system.

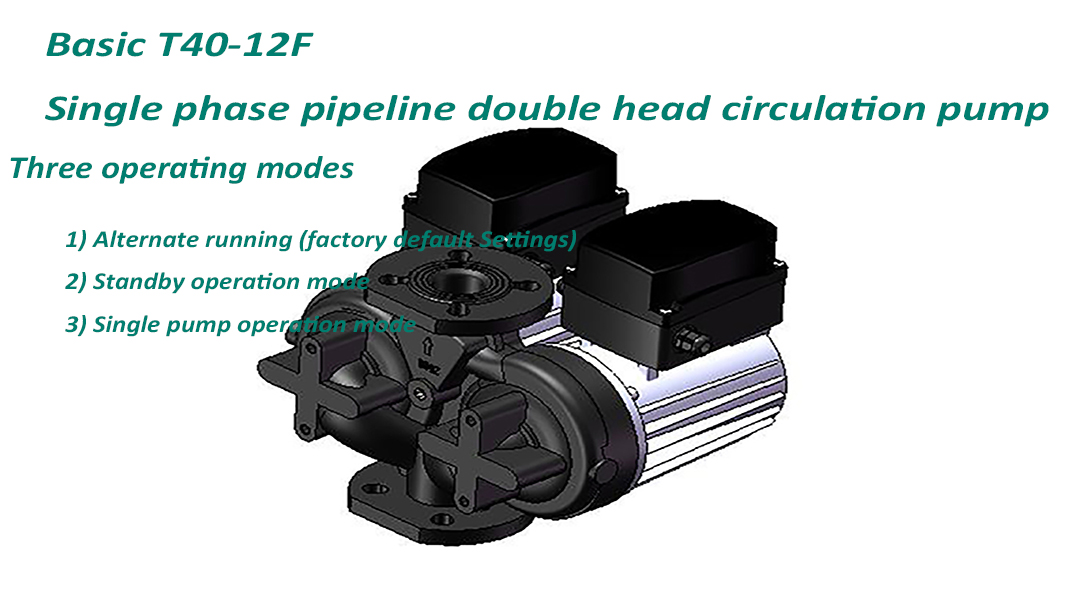

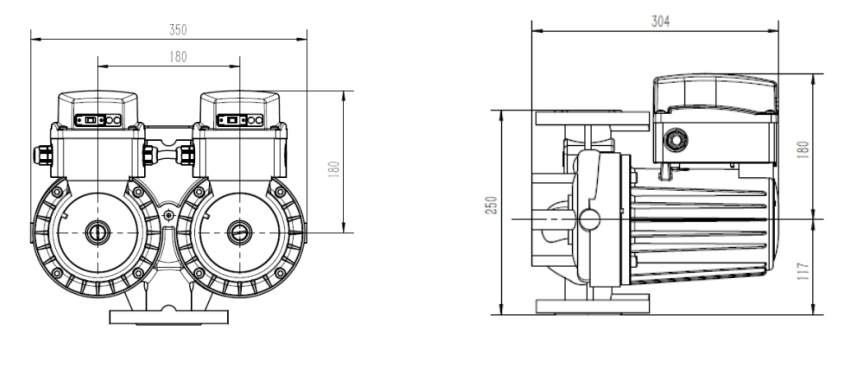

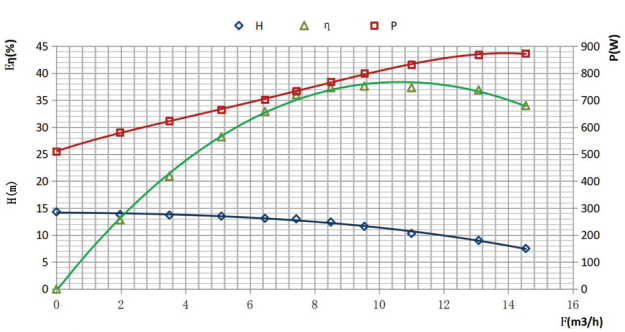

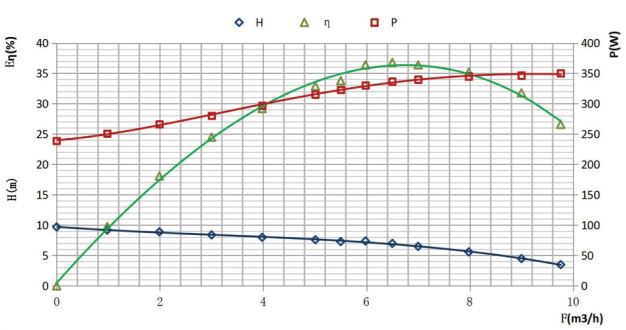

Three-Speed Circulator Pumps

Ideal for HVAC, domestic water supply, and industrial water supply applications, three-speed circulator pumps provide flexibility in adjusting flow rates to match varying requirements. These pumps typically offer three preset speed settings, allowing users to select the appropriate speed based on the system's demand. When selecting a model, consider the flow rate, head, thread and the available speed options. Shinhoo's product line includes Basic , Basic S, Basic Pro and Mega S series, each providing distinct speed and performance characteristics.

Wall Hung Gas Boiler Pumps

Specifically designed for wall hung gas boiler systems, these pumps ensure efficient heat transfer and reliable water circulation. They are compact in size, making them suitable for space-constrained installations. Wall hung gas boiler pumps from Shinhoo are known for their quiet operation and low energy consumption. These pumps ensure proper heat transfer and circulation, contributing to the overall performance of the heating system. When choosing a model, consider factors such as flow rate, head, pressure, compatibility with your boiler system, and the available control options. Shinhoo offers GPA, and GPD series, catering to various wall hung gas boiler system sizes and requirements.

Centrifugal Pumps

Shinhoo's Centrifugal Pumps are versatile and can be employed in HVAC systems, domestic water supply, and industrial water supply applications. These pumps are known for their high flow rates and robust performance. Consider factors such as flow rate, head, pressure, impeller type, and motor power when selecting the right model. Shinhoo's range of centrifugal pumps includes PH, PUN, MHI, F-MHI and SP sereies, each offering different capacities and specifications.

North America Circulator Pumps

Shinhoo's North America Circulator Pumps are specifically tailored for the North American market, meeting the region's safety and certification requirements. These pumps are suitable for HVAC systems and domestic water supply applications. Shinhoo's North America Circulator Pumps come with UL certification, ensuring compliance with the highest safety standards. When selecting a model, consider factors like flow rate, head pressure, and UL certification requirements. Models such as Basic 15-6SFC and Basic 25-10SFC are recommended for North American installations.

Shinhoo offers a wide range of circulation pumps tailored to various home applications. Understanding the specific requirements of HVAC, domestic water supply, industrial water supply, heat pump systems, and wall hung gas boiler systems is crucial for selecting the right pump. By considering factors such as flow rate, pressure, energy efficiency, and compatibility, homeowners can choose the optimal pump model. Whether it's the High Efficiency circulator pumps, Heat pump circulator pumps, Three-speed circulator pumps, Wall hung gas boiler pumps, Centrifugal pumps, or North America circulator pumps, Shinhoo provides reliable and efficient solutions for every home application.